Featured Project: A PBS Metal Building for Hops

We’re excited to share another successful build we were involved with!

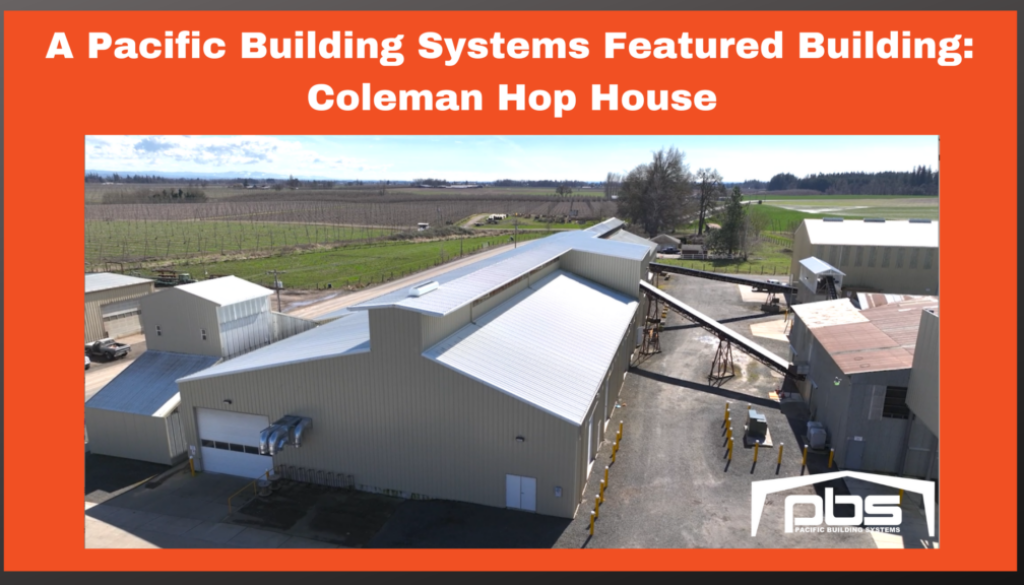

The Coleman Hop House is a pre-engineered metal building for hops that was purchased from Pacific Building Systems by one of our valued customers. This building is made of high-quality materials and it’s sure to provide many years of service to the Coleman hop business.

The Coleman Hop House is a structure that will be used to dry hops. Hops are a type of flower that is used in brewing beer, and they need to be dried on a floor made of wire mesh or burlap while heat is applied from below. The hot air rises up through the hops and exits through the chimney, carrying moisture with it and drying the hops to retain their flavor and aroma.

The Coleman Hop House provides the perfect environment for drying hops, and it will allow the Coleman business to produce hops for the beer industry.

We’re proud to have worked with Coleman Ag on this project, and we’re confident that the Coleman Hop House will be a valuable asset for them. Read on to find out how this project went.

What is the Building Intended to Be Used For?

This building was intended to replace a structure that was used as a perfect replacement to the previous hop kiln. The original building was built in 1944 and had been added on to four times up until 1989. Needless to say, it was time for a proper revamp.

The new building that Pacific Building Systems was able to provide replaced the hop kiln that had been in use for many years. With a new building comes the ability to add upgrades, make renovations, and make improvements to already existing systems.

The pre-engineered metal building they chose allowed them to move into the future with their hop business.

Why Did They Decide a Metal Building Would be Best?

Our customer, the Coleman’s, needed something that would stand the test of time. The original building was starting to weaken in areas and it was important that a new building be brought into the mix.

They first tore down the sections of the original building that were constructed with wood and were deteriorating. The south end of the building was constructed from steel already and they were upgrading the oldest end of the building to start.

The Coleman’s noted in their discussions with us that they were interested in a clear span building with custom roof pitches and we were able and willing to meet their needs.

We were able to create a design and building model for them that would be ideal for their hops operation and would offer them enough space to fully run their business to its highest potential.

When Did They Start Erecting the Building/How Long Did it Take to Build?

They began demolishing the existing structure in November of 2017. This was quite an undertaking before they could move onto the construction of the new building.

After the tear-down process was complete, concrete and footings were poured in January of 2018, and the first steel beams were erected in late March of 2018. The building was then completed in June of 2018.

During construction, much of the internal machinery was installed, which added to the overall construction time. Overall, they’re very happy with their pre engineered metal building.

Were There Any Complications When Erecting the Building and How Did You Overcome These Issues?

This building was very complex. Our customer had to design the rafters around existing conveyors, burners, fans, and other buildings. This was no small feat to take on but it was worth it in the end! They also asked us during the design process to match the existing building in height and roof pitch.

The Coleman Hop House office required constructing a mezzanine suspended from the raised section of the roof to accommodate two conveyors. We were able to work with them on this stipulation and come up with a design that would work around this already existing structure.

This building has numerous roll-up doors for airflow, the building also has an interior liner to keep the area sanitized. The copula is an important part of the hops drying process for removing moisture out of the building.

Knowing that aspects of their business would remain intact, we were up to the challenge of designing a building that was optimal for their needs. As new challenges arrived, our staff was available to answer any questions or help them alter their design. Being flexible is part of the pre-engineered metal building business, especially when it comes to agricultural buildings!

We’re so glad to hear that this building continues to serve them well and that they’ve already seen several successful years under the roof of their metal building. It’s a good reminder too that our pre-engineered metal buildings are versatile and our staff is highly educated, making us an ideal choice for complex buildings.

Typically we see the construction of a metal building from the ground up on a clean slate. However, we’re also ready to help you integrate a pre-engineered metal building into an already existing business landscape.

For help in bringing your metal building dreams to life, reach out to us today!

We’re ready to get started on your design.

Ready to get started?

We have what it takes to make your next project a reality.

Contact a project consultant today.